In most occasions a pitch of three in twelve is preferred but this should also take into consideration the manufacturer s recommendations as well the unique condition of the corrugated metal roof.

How to angle corrugated metal flat roof.

Here is a step by step procedure to help you know how to build a lean to roof.

Corrugated metal roof panels.

Low slope metal roofs require less material which reduces the overall load on the building s structure.

Next pre drill holes on the end and side ridges of the panels spacing the holes 6 to 8 inches apart.

Planning to build a lean to roof but confused whether you can do it or not.

How to seal between metal roofing sheets.

Learn more about the installation of pitch transition trim by watching the short video or reading the transcript below.

To install corrugated roofing start by cutting your panels to length with an angle grinder.

No need to fret it s an easy task and with all the material in place you ll need just two days to install it.

Low slope metal roofs have simple geometries and are easier and less expensive to install that medium to steep slope roofs.

Low slope roofs are not totally flat their roof slope generally ranges from 1 4 12 to 3 12.

You may need to cut panels to fit angles using a circular saw with a metal saw blade.

Water penetration can cost homeowners big bucks when the seams of metal roofing sheets have not been sealed properly.

Although you can install corrugated metal roofing over shingles for the best foundation it is recommended that all the old roofing be removed.

Instructional videos that show your customers how to seamlessly integrate pitch transition trim with our high quality metal roof panels.

Apply butyl tape and waterproof roof.

How to build a strong and sturdy lean to roof.

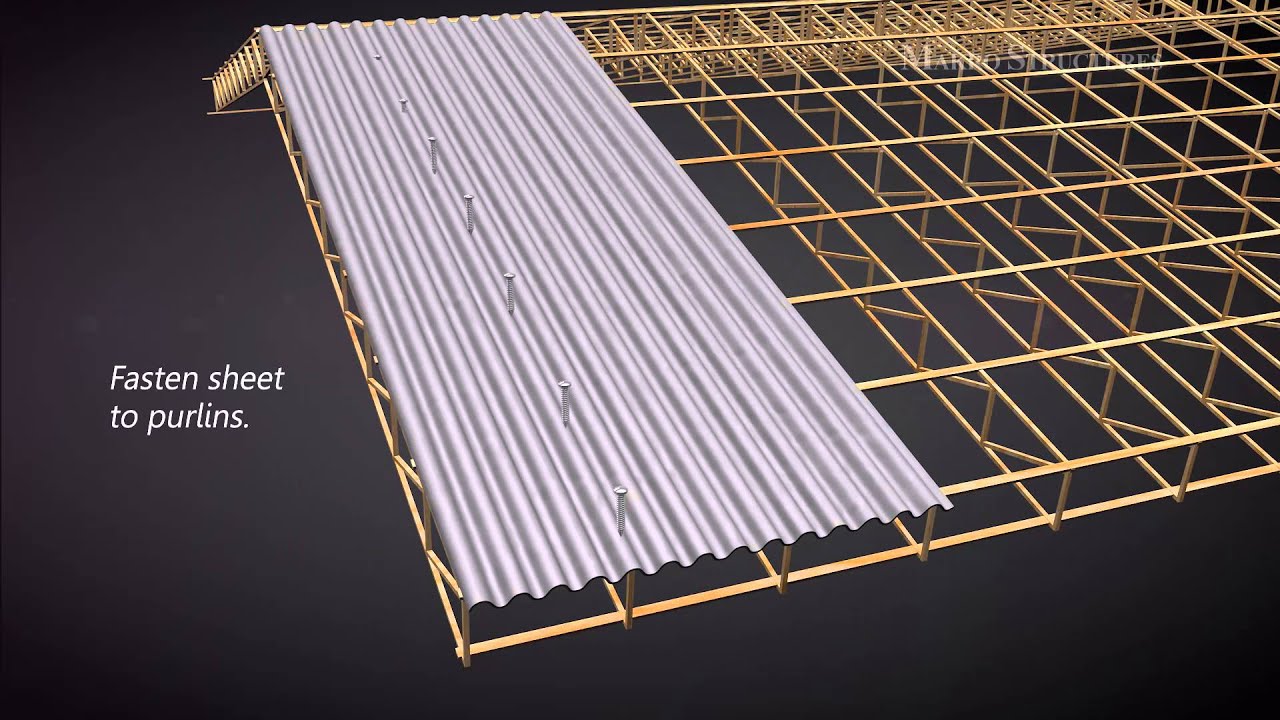

Beginning at the outside edge of your roof place each panel directly onto the purlins that are attached to the roof trusses.

Work at a comfortable steady pace trying not to rip up or carry off too much old roofing at once.